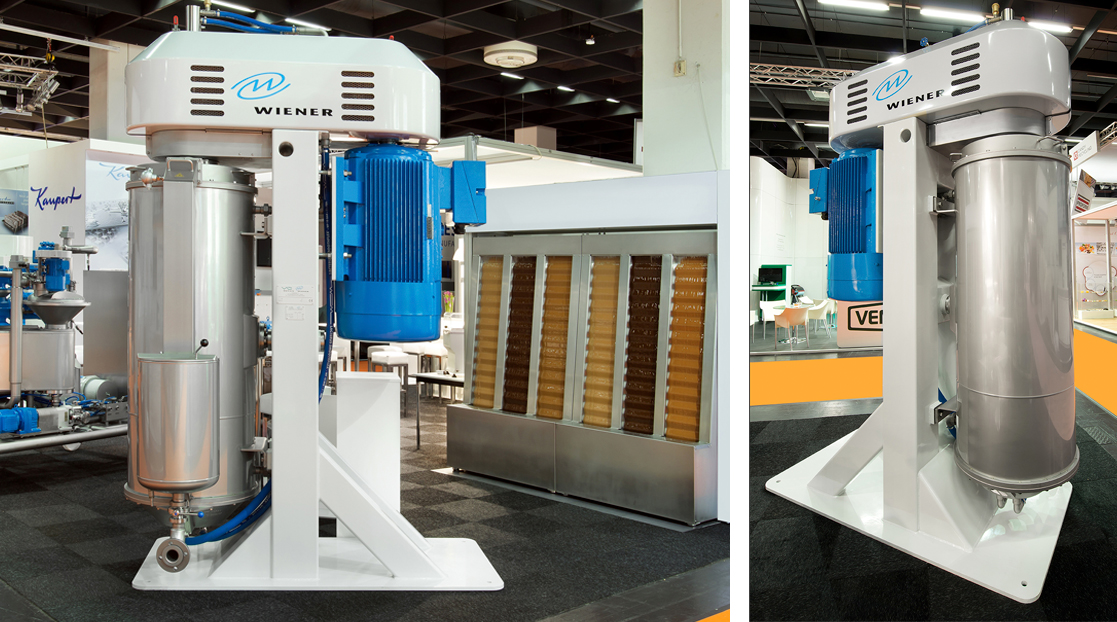

Machine covers

We produce and pre-assemble fibreglass machine covers in various models for one of the world’s largest producers of equipment for the cocoa and chocolate processing industry.

By providing the entire process from production to pre-assembly of these machine covers, we offer the customer one point of contact for the process and quality control. We supply the customer with different models of these machine covers. We produce these by means of hand lay-up and resin transfer moulding (RTM). With resin transfer moulding technology, the total package of fibreglass material and other reinforcements (for example foam parts) is placed in the mould at once. The package is then covered with an upper mould. An advantage of this process is that products are finished smoothly on two sides. This also applies to these machine covers which are delivered directly in a high-gloss finish. The customer then only needs to mount it on his machine.

The design and production in fibreglass offers a number of advantages that contribute to high-quality products. As a result, fibreglass and composite are increasingly being seen in the automotive industry and more and more product designers, architects and engineers are using this material. You can think of applications such as fibreglass; interior design desks, machine hoods, engine hoods, displays, eye catchers, blow-ups, interior wall panels, building façade panels.

Below you will find the advantages of the properties of fibreglass;

- It is light and strong.

- Electrical and thermal insulating.

- Does not conduct electricity or heat.

- Corrosion and chemical resistant.

- Resistant to: weather conditions, temperature fluctuations, acids, bases.

- Low expansion coefficient.

- Not magnetic.

- Low maintenance.

- Freedom in design.

- High impact resistance.

- Available in different colors.

- UV resistant.

- Very long life.

- Good value for money.

Feel free to ask for a quote!

Are you interested in a new product design or do you want to know more about our current projects? Please feel free to contact us via telephone number 023-5283367 or send us an email at [email protected].